Product recommendation

Cottonseed oil has been a marginalized market for a long time. In recent years, with the rapid expansion of the cottonseed oil consumer market, the value of cottonseed has been increasingly recognized by people, and more and more people have entered the cottonseed oil processing industry.

As with other vegetable oil production, when we are preparing to set up a cottonseed oil processing plant, the choice of cottonseed oil processing machine depends largely on the specific oil production process you choose. Therefore, before purchasing all the equipment, it is best to have a simple understanding of the cottonseed oil production process.

Cottonseed oil can be divided into pressed cottonseed oil and extracted cottonseed oil according to different processes. For large-scale cottonseed oil processing, the pre-pressing-leaching process is currently a widely used process. Cottonseed oil processing requires pre-processing work such as delinting, cleaning, shelling, crushing, steaming and frying of cottonseed. The processed cottonseed oil is sent to the pressing workshop for pre-squeezing out the oil. At this time, the pressed cottonseed crude oil is obtained. After the crude oil is squeezed out, the cottonseed cake is crushed and sent to the leaching workshop for leaching to produce oil to obtain the leached crude oil.

The pressing method refers to a method that uses physical pressing and uses mechanical external force to squeeze the oil out of the oil. Preparing cottonseed oil by pressing requires pretreatment equipment + pressing equipment. The pretreatment equipment adjusts the temperature, moisture and internal structure of the cottonseed to bring the cottonseed to a good state before being pressed, which facilitates the extraction of more oil during the pressing process.

Cottonseed oil pressing process: cleaning - shelling and kernel shell separation - embryo rolling - steaming and frying - pressing - filtering;

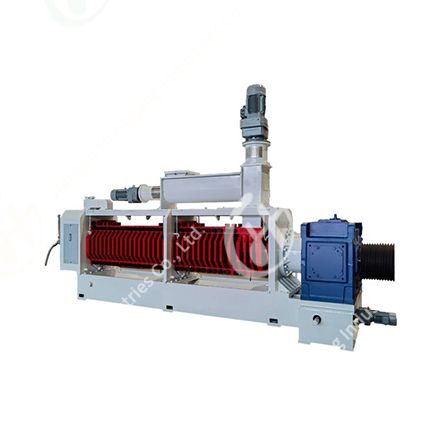

List of cottonseed oil pressing equipment: air separator, sheller, kernel shell separation screen, flaking machine, steaming wok, screw oil press, plate and frame filter.

Pre-pressing and leaching method to produce cottonseed oil requires pre-treatment equipment + pre-press + leaching equipment. The same step as the pressing method is pre-treatment. After pre-treatment and oil extraction by pre-press, the pre-pressed cake is sent to the leaching workshop. In the leaching workshop, the oil in the pre-pressed cake is extracted through the spraying and soaking of n-hexane solvent. Since there is a lot of residual oil in one-time pressing, the pre-pressing and leaching method can obtain more cottonseed oil and bring high economic benefits.

Cottonseed oil leaching process: pre-pressed cake - cottonseed oil leaching - wet meal desolubilization - mixed oil evaporation - solvent condensation recovery - wool cottonseed oil - refining workshop

List of cottonseed oil leaching equipment: edible oil leaching system (leacher), wet meal desolvation system (evaporation tower), mixed oil evaporation system (condenser, long tube evaporator, stripping tower), solvent recovery system.

It should be noted that the pre-pressing and leaching equipment is a relatively complete cottonseed oil production line with a relatively high investment cost, so it is suitable for large and medium-sized cottonseed oil processing plants with a stable daily processing capacity of more than 20 tons/day.