Product recommendation

The wheat grain received by the mill varies in water content and physical characteristics due to the variety and region. Therefore, it is necessary to adjust the water of wheat grains, dry the wheat grains with high water content, and add water appropriately to the low water content to achieve the optimal water content in order to have good flour making properties.

After water regulation, wheat endosperm separation and grinding are required. Traditional milling is the grinding of wheat by rotating the upper and lower stones relative to each other. The mill is generally a 5 ~ 6-storey building, which is equipped with a grinding machine, flat screen and cleaning machine, and the whole process includes skin grinding, slag grinding and core grinding.

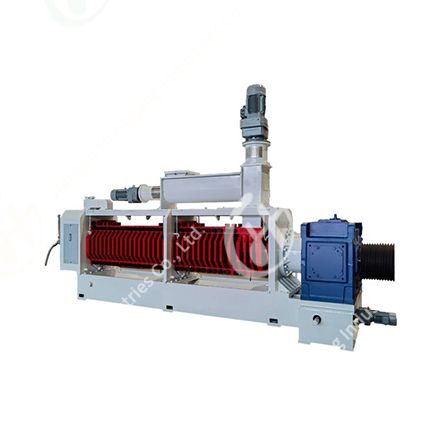

Dermabrasion is mainly used to peel the grain and scrape the endosperm from the seed plate. Generally need to go through 4 to 5 grinding processes, grinding is generally carried out with a roller mill. The cracking effect can be ensured precisely by adjusting the roll gap and roll speed ratio during operation

After grinding, wheat grains enter the sifting machine, and the sifting body is used as a flat screen with plane circular motion for grading. Combined with the air flow through the sifting hole, wheat skin, endosperm with wheat skin and pure endosperm grains are separated.

The endosperm particles of sticky skin separated after skin grinding need to be slag grinding, slight stripping of the grinding roller to further separate the seed coat from the endosperm, and then the purer endosperm particles are recovered through screening. The structure of grinding and screening mechanism used in slag grinding is the same as that of skin grinding system.

Finally, the core grinding, the different particle size of endosperm obtained after skin grinding and slag grinding into powder. The grinding roller of the core mill adopts a smooth roller, which can make a small amount of seed coat and germ mixed into a sheet while the endosperm granules are ground into powder, which is convenient for screening during screening and improve the quality of the finished product.

Finally, the flour mill can also treat a variety of flours, such as adding vitamins and minerals to the flour to increase nutritional value; Add bleach to improve color; Add improvers to improve baking properties, etc.