Product recommendation

The oil produced by soya oil mill plant can be divided into two types: crude oil and refined oil. Crude oil is oil directly obtained by pressing or leaching, and is also called crude oil. Crude oil contains a lot of impurities, some of which will cause damage to the human body if consumed. Therefore, crude oil cannot be directly consumed by humans and needs to be processed into finished soya oil that can be consumed by humans.

The main equipment required for processing soya oil includes soya pretreatment equipment, soya oil leaching equipment, soya oil refining equipment, etc.

Soya oil pretreatment equipment:

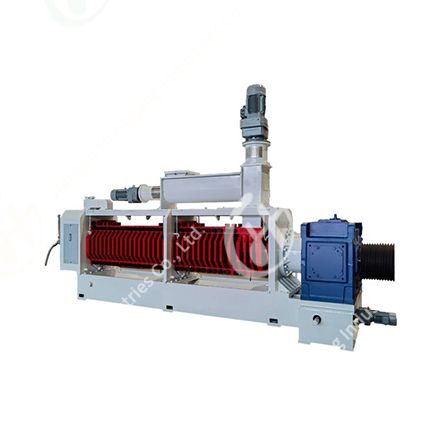

The main function of the soya pretreatment equipment is to process the raw soyas through cleaning, crushing, softening, rolling, steaming and frying to make the soyas into easy-to-leach oil cakes to improve the leaching efficiency. soya pretreatment equipment includes: vibrating screens, destoners, crushers, rolling mills, steaming woks and other equipment.

Soya oil leaching equipment:

The soya leaching equipment fully combines the solvent with the oil to extract the oil in the soya cake to form a mixed oil. The different boiling points of the solvent and the oil are then used to evaporate, separate and recover the solvent to obtain leached soya oil.

The working stages of the soya leaching equipment are divided into five working stages: soya oil leaching - leaching soya meal evaporation, drying and cooling - soya mixed oil evaporation - leaching mixed oil stripping - solvent recovery.

Soya oil refining equipment:

Soya oil refining equipment is the most important equipment for producing different grades of soya oil.

Soya oil can be divided into four grades according to quality standards. Different grades of soya oil require different refining processes. soya oil refining equipment requires six main processes to produce first-grade soya oil, including degumming, deacidification, dehydration, decolorization, deodorization, and dewaxing.

Refining equipment can effectively remove phospholipids, proteins, free fatty acids, moisture, pigments, odorous substances, mechanical impurities, etc. in soya oil from the oil, improve the quality of the oil, ensure the safety of the oil for consumption, and extend the storage time of the oil.