COOKING OIL REFINING PROCESS

Cooking oil refinery process, also called edible oil refinery process or vegetable oil refinery process, are used to process crude vegetable oil into refined edible oil. The refined oil is obtained by refining the crude oil by refining the equipment. It mainly includes degumming, acid removal, decolorization, deodorization and dewaxing.

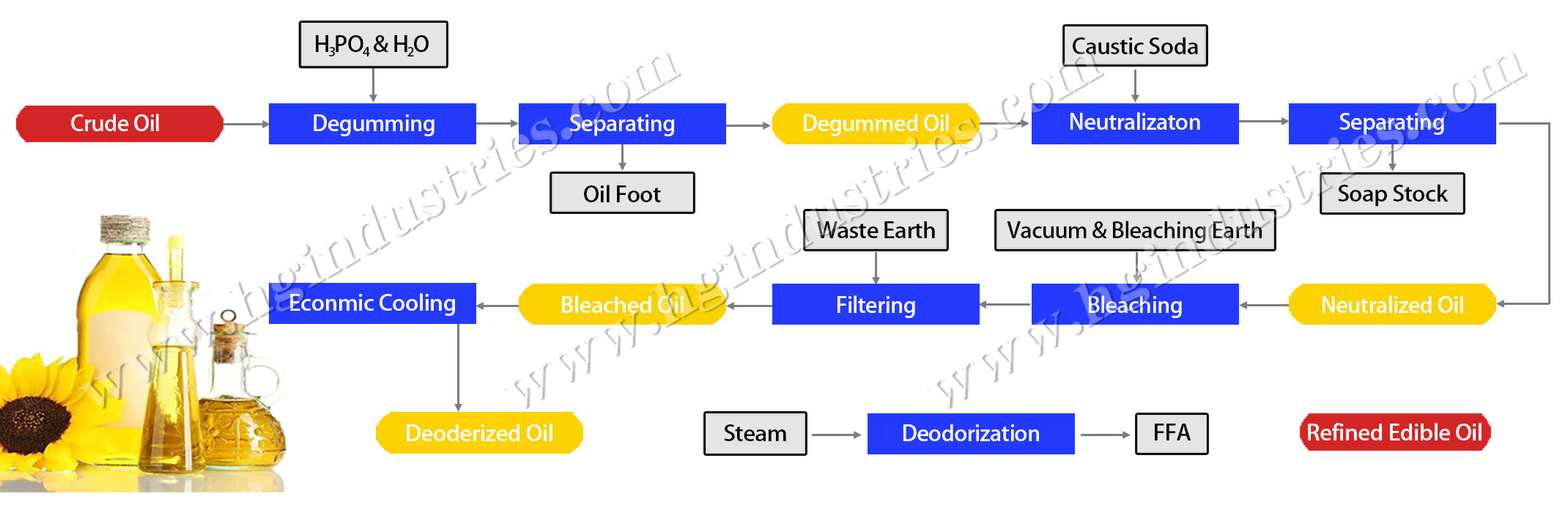

Cooking Oil Refining Process Flow Chart

The main equipment of oil refinery is various kinds of pots and vessels carrying on different tasks with additives. These tasks include part or all processes under: sedimentation/filtering, neutralization, degumming, decolorization, deodorization, dewax (winterization) etc. The selection of steps depends on crude oil quality and refined oil quality requirement. Chemical refining or physical refining can be selected on crude oil condition. '

Capacity | 5T/D -300T/D |

| Process | Neutralization->Degumming->Decolorization->Deodorization->Dewaxing |

Process Advantage:

1. Continuous Neutralization system shorten the contacting time between the oil and caustic, decrease the soapstock amount, lower the waste and increase the oil rate.

2. Negative pressure system ensures the short contacting time of the oil and air, saves the energy consumption and increase the oil quality.

3. Newly developed deodorizing system works in lower temperature, ensures the quality of the oil, decrease the trans fatty acid.

Degumming:

The purpose of Degumming Vegetable Oils is to remove Gums. All oils have hydratable and non-hydratable gums.

a. Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b. Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

Bleaching:

Bleaching is the process operation which is carried out before deodorisation.

In addition to colouring matters, the bleaching treatment using actived earth will remove residual phosphatides, metals, soaps and oxidation products.

Bleaching is performed in 3 stages :

Initial mixing of oil with bleaching earth under controlled conditions of temperature, acidity and humidity for a specific residence time.

Secondly the oil is heated under vacuum with sparge steam to ensure proper mixing with bleaching earth for a specific residence time.

Finally the mixture is pumped through hermetic leaf filters with stainless steel mesh elements followed by polishing filtration.

Spent cake is dried by steam blowing to remove the oil from the wet cake.

Deodorization:

Deodorising is the final stage in oil refining. Deodorising removes odoriferous material, free fatty acids and other undesired minor components to produce a bland oil with a good shelf life.

The different stages in deodorising are :

● Deaeration

● Heating

● Deodorising/steam stripping

● Heat recovery/cooling

● Final cooling

● Polishing filtration

● Top quality products require optimal conditions at all stages.

Winterization:

This process is also known as the dewaxing process. It is a thermo-mechanical process to crystallize the solid particles left in the oil. A crystallization agent is added to the oil and allowed to cool.

After crystallizing these particles, mechanical separation helps to remove them. This process is usually done on cotton and sunflower seed oil.