PET FOOD EXTRUDER

Our company animal food machine are equipped with the latest process technology, the core of which is the extrusion system with the extruder and the process control system .In the production process, the raw materials undergo the process steps of weighing, fine grinding, mixing,extrusion, drying, vacuum coating,cooling and packaging.

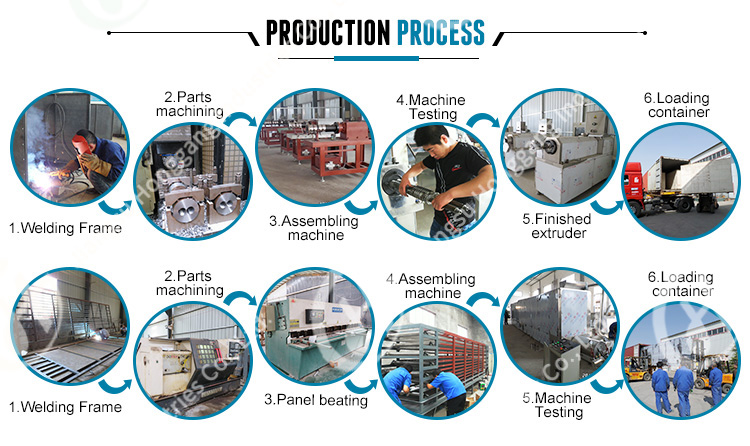

![]() Process flow of pet food production line

Process flow of pet food production line

1. Crushing of raw materials → preparation of raw materials (corn flour, soybean meal, starch, fish meal, etc.) → mixing machine → conveyor → twin-screw feed extruder → transportation → drying equipment (electric oven, gas fuel oil oven or steam oven) → oil injection → Double-barrel seasoning system → cooling conveyor → screening → silo → packaging machine

2. Process composition of pet feed production line: Sandwich pet food production line Sandwich dog food production equipment Sandwich cat food nutrition production machine, loved by customers!

3. This pet food production line is solved. The small single-screw dog food machine has insufficient puffing degree. It is difficult to clean the screw every time the production is completed. The proportion of fresh meat and bone mud added is limited and the screw wear is fast. Dog farm and personal entrepreneurs love.

![]() Equipment introduction

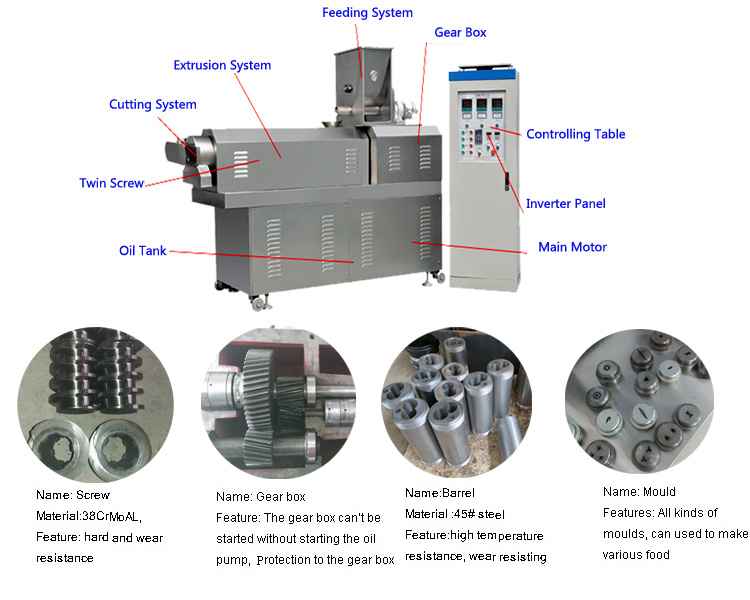

Equipment introduction

1. Mixer: mix raw materials corn flour, rice flour, soybean meal, fish meal, meat meal, cereal meal, additives, etc. with a certain proportion of water to mix them evenly.

2. Feeding machine: the motor is used for power screw conveying, and the stirred raw materials are sent to the feeding hopper of the twin screw extruder. The feeding of this equipment is convenient and fast, saving labor and high efficiency.

3. Twin-screw feed extruder: Under the high-temperature and high-pressure environment and twin-screw extrusion conditions, the structure of the starch in the raw material changes and becomes easily absorbed nutrients. It is extruded through the feed mold and adjusted by rotary cutting. The speed of the motor until the speed of the feed pellets is the same size. The specific particle size and shape are obtained by replacing the mold. The feed extruder adopts advanced frequency conversion speed regulation technology, which is more energy-saving and the speed control is more accurate. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment.

4. Conveyor: convey the produced feed particles to the multi-layer drying equipment.

5. Multi-layer oven: The oven is divided into electric oven, fuel oven, gas oven and steam oven. The temperature is adjusted by the control cabinet between 0 and 150 degrees. The interior of the oven is stainless steel mesh belt, which has stable transmission and low failure rate. The feed pellets circulate through multiple S-shaped tracks to dry the feed pellets to a safe water content and increase the shelf life.

6. Spraying seasoning line: The oil sprayer sprays oils, attractants, etc. The seasoning tube has octagonal tube, cylinder, lifting single drum, double drum seasoning line, according to the output and product nature configuration, spray the fat on the feed surface, Spray minced meat and spices at the same time and sprinkle evenly. After this process, the burrs and burrs on the surface of the feed pellets can be removed to make the surface of the feed pellets smoother.

7. Cooling conveyor: reduce the temperature of the surface of the dried feed pellets, promote the solidification of grease, reduce the pellet temperature, and facilitate packaging.

8. Vibrating sieve: sieve out extra material and granule slag to ensure the quality and reuse of raw materials.

9. Packaging machine: manual sealing machine and automatic packaging machine can be used, please call the manufacturer for details.

![]() Pet food production line Equipment advantages

Pet food production line Equipment advantages

1. The built-in screw and screw sleeve of the dog food equipment model are extended, the material rotation time is long, the temperature can be adjusted, and the output torque can be adjusted, so that the resulting material has a high degree of expansion and a smooth surface.

2. Different feeds can be made, this model can do: suspended aquatic feed pellets, sinking fish, shrimp and crab feed pellets, pet feed pellets, hanging fish feed pellets, etc.

3. The international advanced pelletizing structure adopts the soft knife fitting form to realize the stepless speed change, which can cut the discharge material into the required length products at will, and it is not easy to produce burrs.

4. Novel design, unique, simple structure, easy to install, easy to disassemble, easy to operate.

5. The screw sleeve and screw are made of special wear-resistant and high-temperature alloy steel materials and are heat-treated, which has the advantages of wear resistance and long life.

6. A unique pressure-increasing die device is installed to ensure the output and quality of the feed, and an electric heating device is provided to improve the feed expansion rate.

7. The main motor adopts high-quality Y series two-phase and three-phase motors to ensure strong power.

8. The speed-adjusting feeding device is more convenient to operate, the feeding is uniform, and it prevents the machine from holding back.

9. The replacement of the discharge template is simple, if different aperture feeds are needed, only the required aperture template can be replaced

|

|

| You can use this animal food making machine to produce different size pellet by change the extruder dies easily. | Our company engineer go to customer factory to help them and training workers on the spot. |

|  |