Comparison of different types of oil presses

2023-11-16

Comparison of different types of oil presses

Oil press is a key equipment used to extract crude oil from raw materials such as camellia seeds. There are two main processes: intermittent and continuous, and different types of oil presses are suitable for these processes. The following is a brief introduction to the different types of oil presses:

Hydraulic oil press: This is a traditional small oil press, the production process is intermittent. The operations requiring pretreatment include husking and separation of the kernel, as well as breaking the kernel into small particles, which are preferably rolled and pressed after frying with a pan or rotary pan. The operation of this oil press has low technical requirements, higher oil yield and better gross oil quality, but it requires greater manpower input. Suitable for small-scale production, the daily processing capacity is about 1 ton.

Small power screw oil press: This is a continuous oil press, the representative model is 95 oil press, there are a variety of improved models. This type of machine has less requirements for pretreatment, only need to break the grain into small particles after stir-frying, and the shell is not a necessary process. This kind of machine has low technical requirements and high oil yield. The quality of the gross oil is worse than that extracted by the hydraulic oil press, and the labor intensity is relatively low. Suitable for small-scale production, each machine can handle about 5 tons per day. It should be noted that this type of oil press may have problems with slippage and non-feeding, especially when dealing with shelled oil tea seeds.

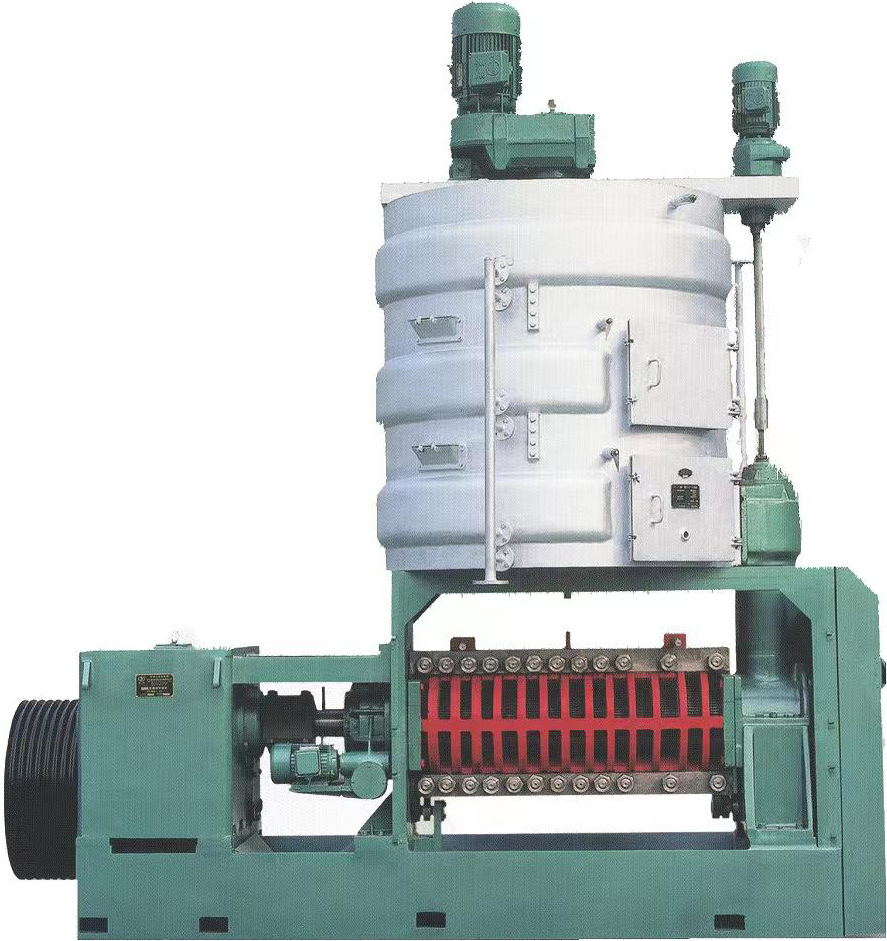

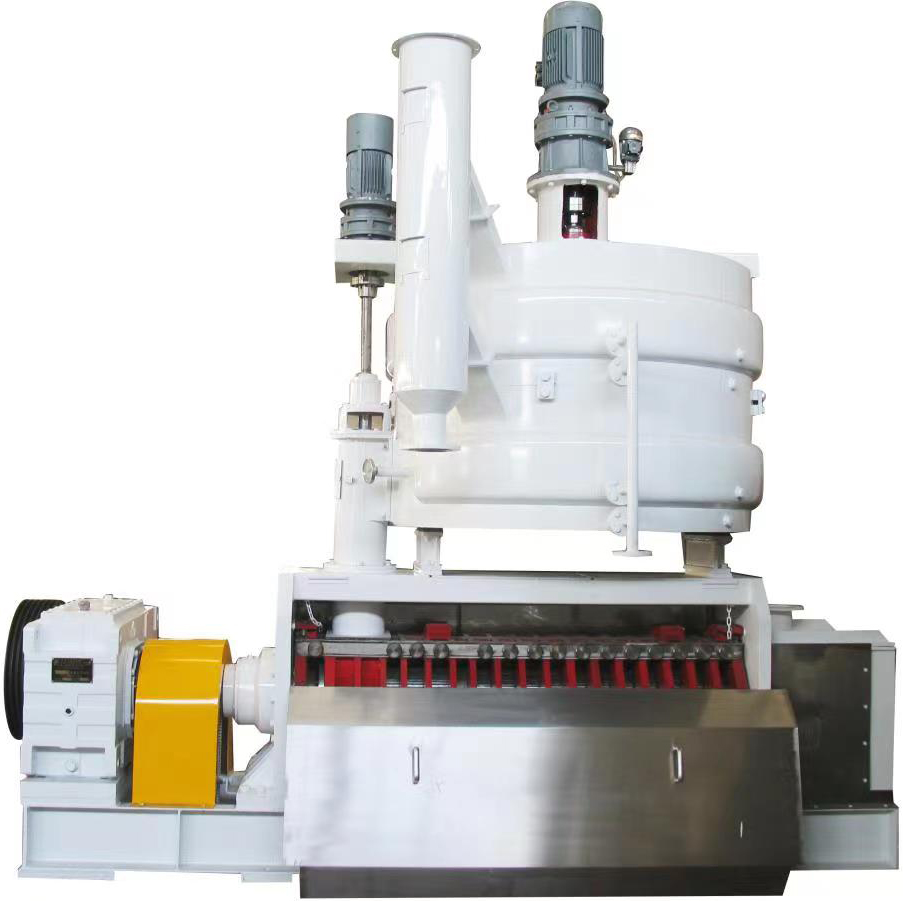

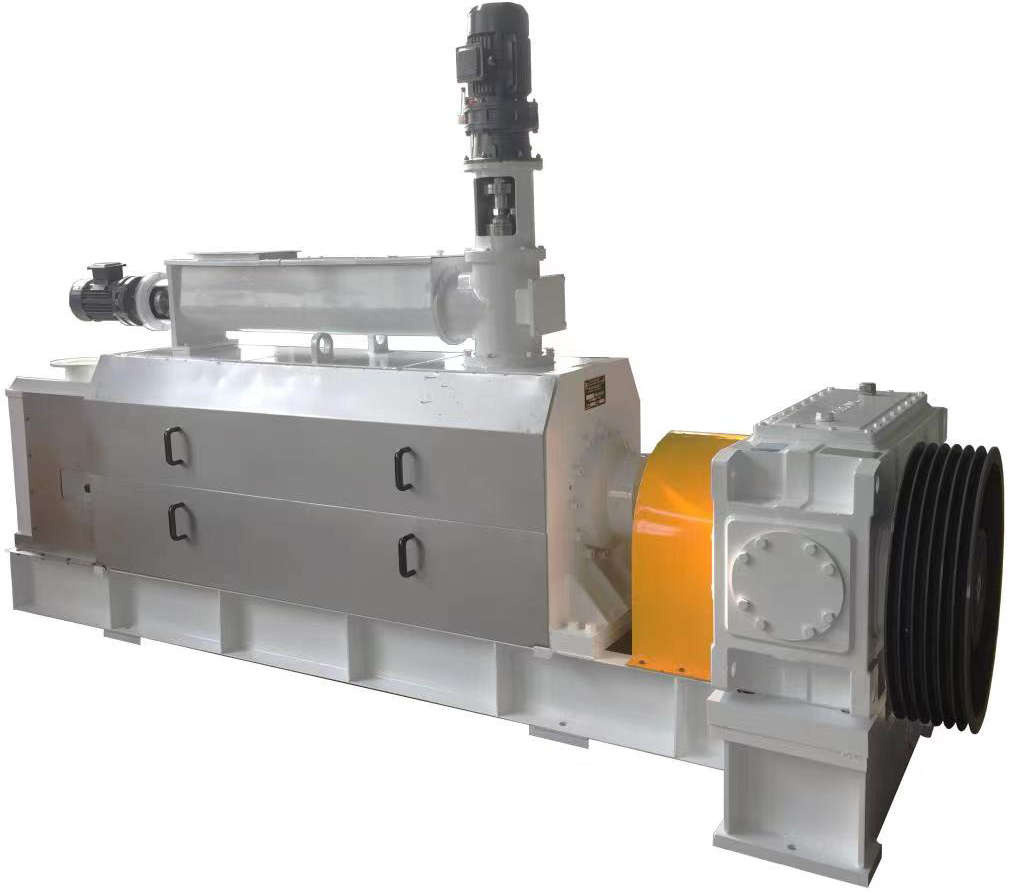

Large and medium-sized power screw oil press: This machine is suitable for large-scale, continuous production plants. During pretreatment, the seeds should be cleaned, broken into smaller particles, and then rolled, and steamed and stir-fried with multi-layer (such as five-layer) steaming pan. The production of this oil press is continuous, the labor intensity is low, but the oil yield is low, and it is usually used for the pre-pressing process (after the leaching process), and the operation technical requirements are higher. Similarly, like the small screw press, the large machine may also have problems with slippage and non-feeding, and it is necessary to choose the right model or make appropriate modifications to solve these problems.

|  |  |