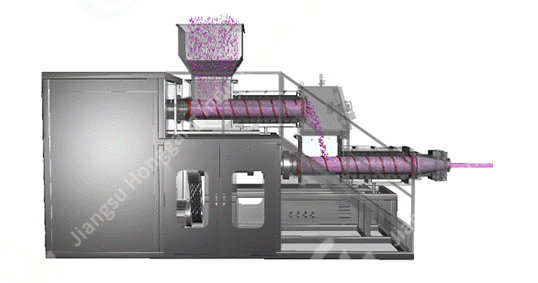

Plodding Machine

This equipment adopts hard tooth surface reducer with vacuum pump. With Feature of wear and tear, low noise and long lifetime. The screw use stainless steel welded together with anticorrosion and durable features. Inner roller adopts high quality seamless stainless steel pipe with pressive strength and non-deforming features while outer roller using cooling jacket. Control part adopts frequency conversion or electromagnetic variable-speed motor. It can be produced many types of toilet soap as well as transparent soap with different fatty acid content.

Details

Application:

This equipment adopts hard tooth surface reducer with vacuum pump. With Feature of wear and tear, low noise and long lifetime. The screw use stainless steel welded together with anticorrosion and durable features. Inner roller adopts high quality seamless stainless steel pipe with pressive strength and non-deforming features while outer roller using cooling jacket. Control part adopts frequency conversion or electromagnetic variable-speed motor. It can be produced many types of toilet soap as well as transparent soap with different fatty acid content.

Main Technical Data

Model | SYJ-500 | SYJ-800 | SYJ-1000 | SYJ-2000 |

Production Capacity (Kg/h) | 500-600 | 800-900 | 1000-1200 | 1500 - 2000 |

Outer Roller Of Screw (mm) | 4)200 | 0228 | 0280 | 0300 |

Power Consumption (Kw) | 11 + 15 | 15+18.5 | 18.5 + 22 | 30+30 |

Revolution Of Screw (r/min) | 18(1 st Stage) 10-18(2nd Stage) | 18(1 st Stage) 10-18(2nd Stage) | 18(1 st Stage) 10-18(2nd Stage) | 18(1 st Stage) 10-18(2nd Stage) |

Gross Weight (Kg) | 3800 | 4500 | 5500 | 7000 |

Working Principle

The first is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper.