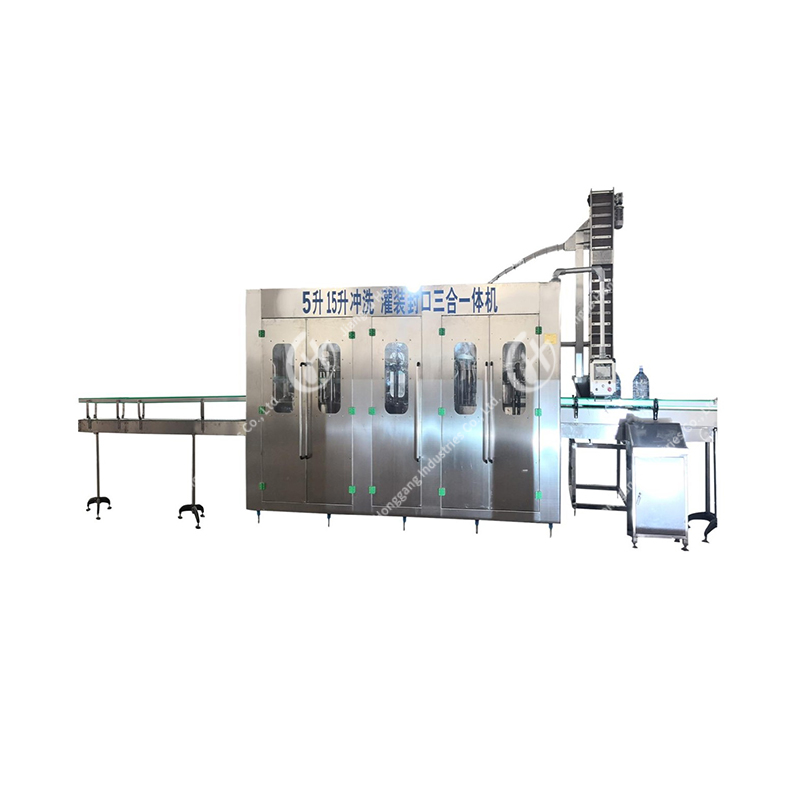

Disposable barrelled water filling machine

1.The 5-15 L bottled water production line is exclusively used for 5-15 L bottled water production. 2.Washing, filling and capping are achieved on one machine. 3. The bottle washing machine uses multiple washing liquid injection and disinfectant injection to achieve the purpose of washing and disinfection, and the disinfectant can be recycled. 4. The seal can seal automatically to ensure that the cap is sterile and clean. 5. The production line has compact structure, small area and high degree of automation. 6. The key appliances are Siemens, Mitsubishi, Schneider, Omron and other well-known products.

Details

Disposable barrelled water filling machine

Characteristic:

1.The 5-15 L bottled water production line is exclusively used for 5-15 L bottled water production.

2.Washing, filling and capping are achieved on one machine.

3. The bottle washing machine uses multiple washing liquid injection and disinfectant injection to achieve the purpose of washing and disinfection, and the disinfectant can be recycled.

4. The seal can seal automatically to ensure that the cap is sterile and clean.

5. The production line has compact structure, small area and high degree of automation.

6. The key appliances are Siemens, Mitsubishi, Schneider, Omron and other well-known products.

Technical Data:

| Model | XGF 9-9-4 | XGF 12-12-5 | XGF16-16-5 | XGF20-20-5 |

| Rinse head number | 9 | 12 | 16 | 20 |

| Filling head number | 9 | 12 | 16 | 20 |

| Cap head number | 4 | 5 | 5 | 5 |

| Output(B/H)10L | 800-1000 | 1200-1500 | 2000-2500 | 3000-4000 |

| Power(KW) | 4.0KW | 5.5KW | 6.0KW | 8.0KW |

| Size(m) | 2.6*2*2.4 | 3*2*2.4 | 3.5*2.5*2.4 | 3.7*2.8*2.5 |

| Weight(KG) | 5000KG | 6000KG | 6500KG | 8000KG |

Barreled water engine

Characteristic:

1、Automatic bottled production line QGF series for 3-5 gallon bottled drinking water.

2、The series of production line consists of three parts: bottle washing, filing and sealing.

3、The bottle washing machine adopts multi-channel washing liquid injection and disinfectant injection to achieve the purpose of washing and disinfection, and the disinfectant can be recycled

4、The sealing machine can automatically seal, and the spray device is equipped during the bottle cap process to ensure that the bottle cap is sterile and clean.

5、The series of production lines can automatically wash, disinfection, filing, capping, counting and output.

6、The key electrical appliances are Siemens, Mitsubishi, Schneider, Omron and otherwell-known products.

7、The production line has compact structure, small area and high degree of automation. lt is the ideal equipment for mineral water, steamed water and pure water production.

Technical Data:

| Model | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Rinse the number of channels | 4 | 4 | 4 | 4 | 4 | 4 |

| Filling head number | 1 | 2 | 3 | 4 | 6 | 8 |

| Cap head number | 1 | 1 | 1 | 1 | 1 | 1 |

| Output(B/H)18.9L | 150 | 300 | 450 | 600 | 900 | 1200 |

| Power(KW) | 1.5KW | 3.8KW | 4.5KW | 7.5KW | 9.5KW | 13.5KW |

| Additional voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Weight(KG) | 800KG | 1500KG | 2200KG | 3500KG | 5000KG | 6000KG |