Water Pump Bearing

Our Water Pump Bearing is engineered to deliver exceptional performance and reliability in automotive water pump applications. Designed for longevity, it is built with premium materials to withstand extreme temperatures and harsh environments, ensuring a smooth and efficient operation of the water pump system. This Water Pump Bearing is compatible with a wide range of vehicles, including cars, trucks, and commercial vehicles. Whether you’re replacing a worn-out bearing or upgrading your water pump system, our bearing provides the durability and reliability you need for peace of mind on the road.

Details

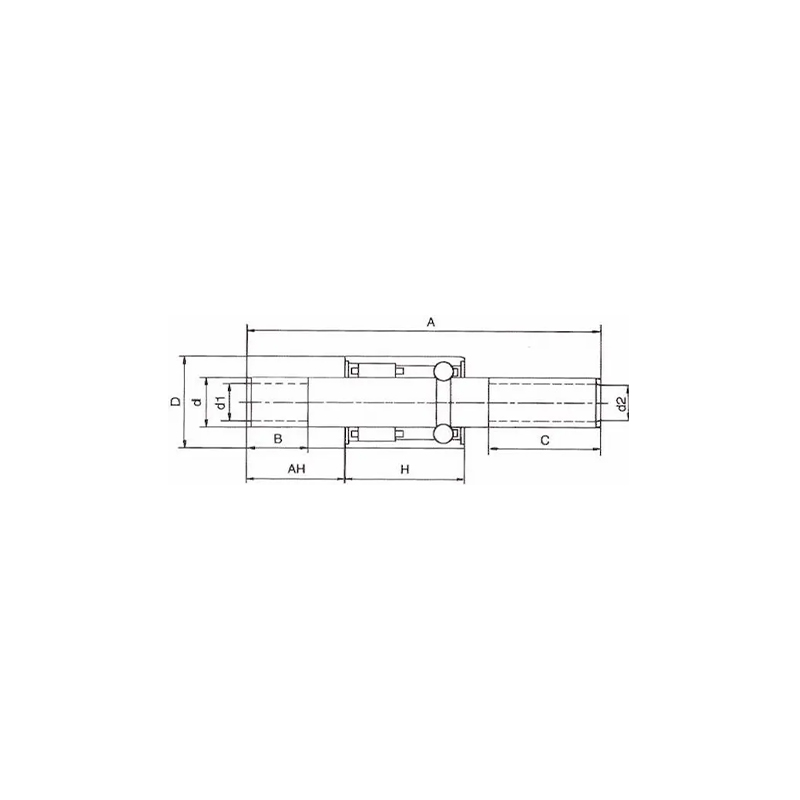

Comprehensive Overview of Ball Roller Type Water Pump Bearings

Construction

Outer Rings and Shaft: The ball roller type water pump bearing features an outer ring and shaft made from high-quality steel or alloy. This construction provides the necessary strength and durability to support the rotational motion of the water pump shaft effectively. The shaft is equipped with grooves designed to accommodate the rollers and balls, facilitating smooth and efficient operation.

Roller and Ball Elements: Distinct from traditional ball bearings, this bearing type incorporates cylindrical or tapered rollers rather than spherical balls. These rollers offer a larger contact area with the inner and outer raceways compared to ball bearings. This increased surface area enhances the bearing’s load-carrying capacity and durability, making it suitable for applications requiring robust performance under varying conditions.

Sealing Mechanisms: The ball roller bearing is equipped with advanced sealing mechanisms, including seals or shields, designed to protect against contaminants such as water, dust, and debris. This protection is crucial for maintaining the bearing’s longevity and performance, especially in harsh operating environments where exposure to external elements is a concern.

Performance and Applications

Load Capacity: The robust design of ball roller bearings allows them to handle heavier loads and higher speeds compared to conventional ball bearings. This makes them ideal for use in automotive water pumps and industrial pumping systems, where reliable performance under varying conditions is critical. Their ability to manage substantial loads and withstand stress contributes to their effectiveness in demanding applications.

Heat Dissipation: One of the advantages of the ball roller bearing is its efficient heat dissipation. The larger contact area between the rollers and raceways facilitates better heat management, which enhances the bearing’s operational reliability and extends its service life. This is particularly important in applications where heat buildup could affect performance and longevity.

Versatility: Ball roller bearings are versatile components suitable for a broad range of water pump applications. They are commonly used in automotive cooling systems, agricultural irrigation setups, HVAC units, and various industrial processes. Their dependable performance makes them a preferred choice in situations where consistent operation is essential.

Quality Assurance

Materials and Manufacturing: Our ball roller bearings are manufactured using advanced production techniques and adhere to stringent quality control standards. High-grade materials are selected to ensure durability and reliability. The meticulous assembly process ensures that each bearing meets the required precision and performance criteria.

Testing and Certification: Each bearing undergoes rigorous testing to verify its dimensional accuracy, load-bearing capacity, and resistance to environmental factors. These tests ensure that the bearings comply with industry standards and meet customer specifications. Certification processes further validate the bearing’s quality and reliability.

Tips for Optimal Performance

Proper Installation: To ensure the bearing operates correctly, use the appropriate tools and techniques for installation. Adhere to the manufacturer’s specifications for torque and alignment to prevent damage. Avoid excessive force during installation, as this can harm the bearing or its components.

Regular Lubrication: Follow the manufacturer’s recommendations regarding the type and amount of lubricant to use. Regularly check and replenish the lubricant to maintain optimal bearing performance. Ensure that the lubricant is clean and free from contaminants to prevent issues.

Correct Fit and Alignment: Verify that the bearing fits properly within its housing and on the shaft to avoid misalignment. Regularly inspect for signs of misalignment, which can lead to uneven wear and premature failure. Use precision tools to measure and adjust alignment as needed.

Proper Handling: Handle bearings with care during transportation and installation to avoid physical damage. Use clean gloves to prevent contamination from oils and dirt. Avoid dropping or striking the bearing, as such impacts can cause dents and affect performance.

Load Management: Ensure that the bearing is not subjected to loads beyond its rated capacity. Avoid shock loads or sudden impacts that can damage the bearing. Distribute loads evenly to prevent localized stress on the bearing components.

Conclusion

The ball roller type water pump bearing excels in providing robust performance and reliability in challenging operational environments. Its superior load capacity, efficient heat dissipation, and effective sealing mechanisms make it an ideal choice for critical applications where dependable performance is essential. By following proper maintenance and handling practices, you can maximize the longevity and efficiency of your water pump bearings, ensuring smooth and reliable operation for your machinery.

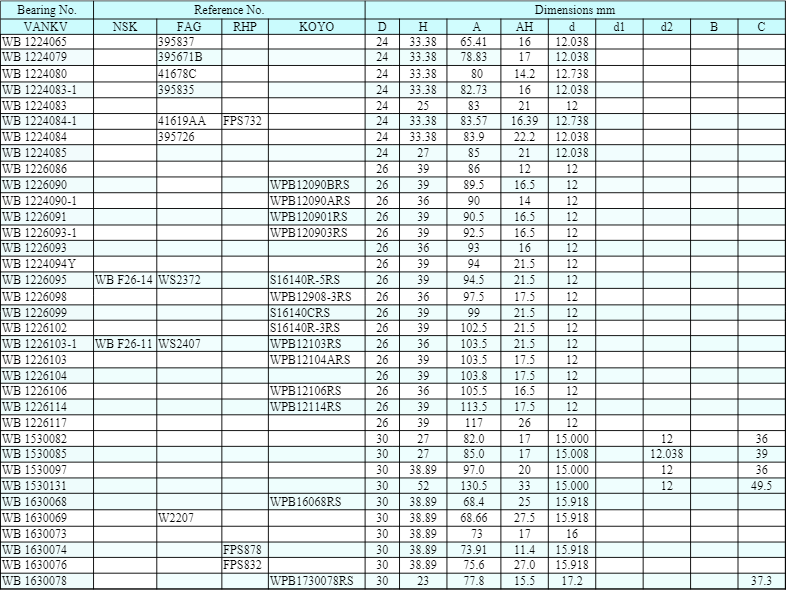

Technical Data:

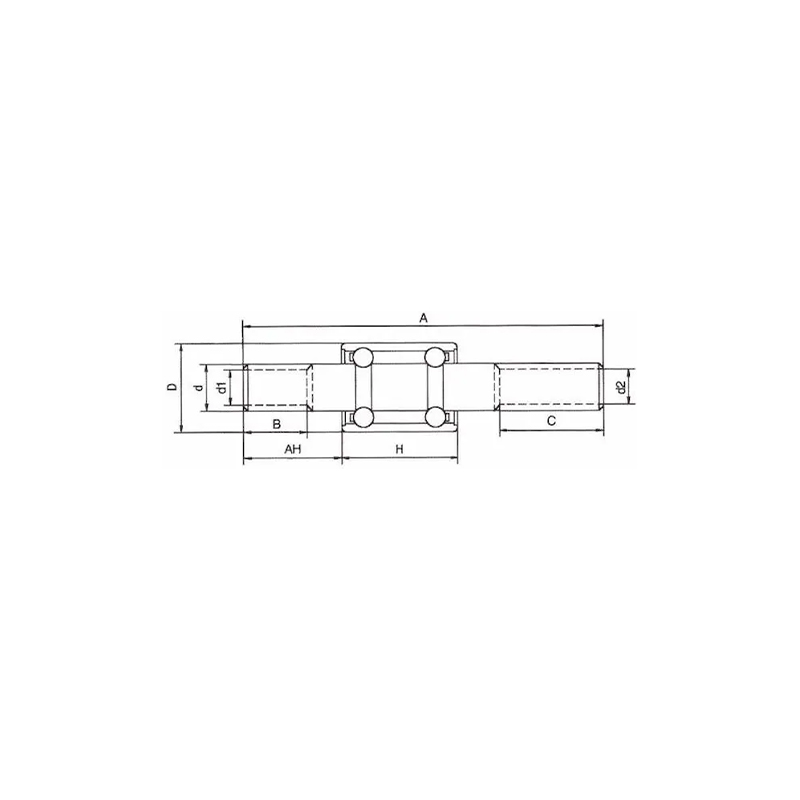

Water Pump Bearing (Ball-Ball Type): Construction, Functionality, Applications, and Quality Assurance

Ball-Ball Type Water Pump Bearings are engineered for excellence in both automotive and industrial water pump applications. Their robust design and high performance make them essential components in various critical systems.

Design and Construction

Ball-Ball Type Water Pump Bearings are meticulously crafted to ensure optimal durability and efficiency. These bearings feature a solid outer ring that firmly attaches to the water pump shaft, providing stability during operation. Internally, they utilize a dual-row configuration of steel balls, which are precisely spaced and separated by a cage to facilitate smooth motion and reduce friction. This setup is crucial for handling substantial radial and axial loads.

The bearings may also include seals or shields, depending on the application. These protective elements are vital for preventing the ingress of contaminants such as water, dirt, and debris, while retaining essential lubrication.

Functionality and Performance

The Ball-Ball Type Water Pump Bearing is designed to offer reliable and efficient performance across a range of operating conditions. Its dual-row ball arrangement enhances the bearing’s load-carrying capacity, managing both radial and axial stresses commonly encountered in water pump systems. The bearing performs efficiently at varying speeds, with its design minimizing friction and heat generation to ensure smooth operation even under high rotational speeds.

The presence of seals or shields is integral to its functionality, extending the bearing’s service life by protecting it from external elements and maintaining its performance in challenging environments.

Applications

These bearings are employed in several crucial applications:

Automotive Industry: In vehicles, Ball-Ball Type Water Pump Bearings are essential for circulating coolant through the engine, helping to prevent overheating and ensuring optimal engine performance. Their reliability is critical for maintaining proper operating temperatures.

Industrial Settings: In industrial environments, these bearings are used in water pumps for tasks such as agricultural irrigation, HVAC systems, and various process industries. They are vital for maintaining continuous and efficient operation across these applications.

Quality Assurance and Durability

Ensuring the quality and longevity of Ball-Ball Type Water Pump Bearings involves a rigorous quality control process. Bearings are manufactured from high-grade steel or stainless steel, chosen for their resistance to corrosion and wear in harsh conditions. Advanced machining techniques are employed to achieve precise dimensions and tight tolerances, with automated processes and stringent quality controls ensuring consistency.

Each bearing undergoes comprehensive testing, including dimensional accuracy checks, load capacity tests, rotational speed evaluations, and endurance simulations to verify long-term reliability. Our manufacturing processes comply with international standards such as ISO 9001, and we conduct regular audits to maintain high-quality standards. Continuous improvements are driven by customer feedback, enhancing both technology and performance.

Maintenance and Handling

To optimize the performance and lifespan of Ball-Ball Type Water Pump Bearings, adhere to the following guidelines:

Installation: Use the correct tools and follow manufacturer specifications for torque and alignment to avoid damage. Avoid excessive force during installation.

Lubrication: Apply the recommended lubricant type and amount. Regularly check and replenish lubrication, ensuring it remains clean to prevent bearing damage.

Fit and Alignment: Verify that the bearing fits correctly and use precision tools to adjust alignment as necessary.

Handling: Handle bearings carefully to avoid physical damage and contamination. Prevent dropping or striking the bearing.

Environmental Protection: Use seals and shields to protect against contaminants. Store bearings in a clean, dry place.

Inspection: Regularly inspect bearings for wear, damage, or other issues. Replace bearings showing signs of deterioration to prevent failures.

Temperature Control: Monitor operating temperatures and provide adequate ventilation and cooling to avoid overheating.

Load Management: Ensure the bearing does not exceed its rated load capacity and avoid sudden impacts that could cause damage.

By following these practices, you ensure that Ball-Ball Type Water Pump Bearings deliver reliable performance and durability, whether in automotive or industrial applications.

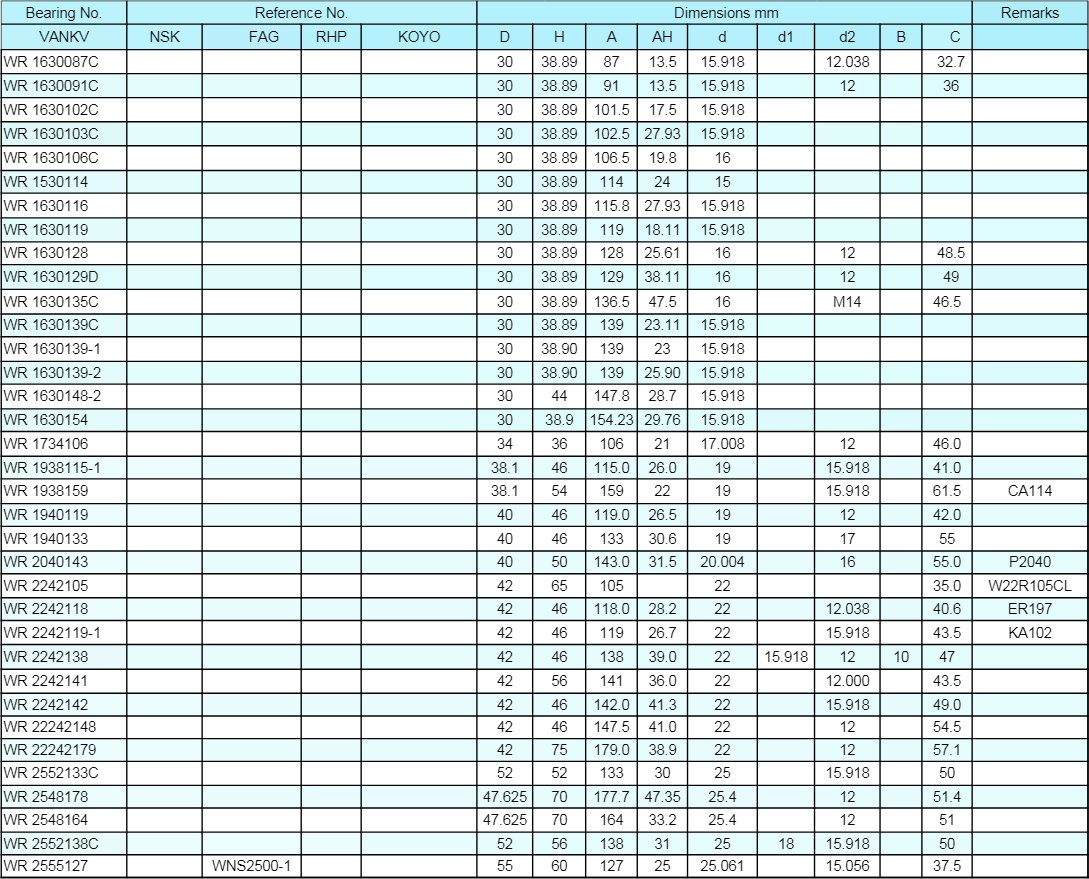

Technical Data: