Wheel Hub Bearings DU/DAC

Our Wheel Hub Bearing is meticulously engineered to ensure the smooth and safe operation of your vehicle’s wheels. Designed to withstand the rigors of daily driving, this bearing is made from high-quality materials that offer exceptional durability and performance. Whether you’re driving on the highway or navigating rough terrain, our wheel hub bearing provides the stability and reliability you need for a comfortable ride. Designed to fit seamlessly with most vehicle models, our wheel hub bearing allows for quick and easy installation, reducing downtime.

Details

Design and Structure of Double Row Tapered Roller Bearings

Tapered Rollers

Double row tapered roller bearings are engineered to manage substantial radial and axial loads from both directions, making them crucial for high-demand applications. The rollers are arranged in two rows, each positioned with a precise taper that facilitates optimal load distribution. This design minimizes stress on the rollers and extends the bearing’s lifespan.

Roller Design: The tapered shape of the rollers allows them to make contact at a more extensive angle with the raceways. This ensures an even distribution of load and enhances the bearing’s ability to handle significant forces. The design also helps in reducing stress concentrations, leading to greater durability.

Inner and Outer Rings

The inner and outer rings, also known as the inner and outer races, form the core structural components of the bearing. These rings are meticulously engineered to provide a perfect fit for the tapered rollers, ensuring efficient load transfer and minimizing wear.

Ring Material: Typically crafted from high-strength steel, the rings are heat-treated to increase their hardness and resistance to wear. This material choice and treatment are crucial for maintaining the bearing’s performance under heavy loads and harsh conditions.

Retainer

The retainer, or cage, plays a vital role in maintaining the bearing’s functionality. It spaces the rollers evenly and prevents them from coming into contact with each other, which is essential for smooth operation and reduced friction.

Cage Functionality: The retainer helps to prevent roller skewing and misalignment, which can lead to premature wear or bearing failure. Its design ensures that each roller operates independently within its designated space, enhancing overall efficiency.

Seals

Sealing technology is integrated into the design to protect the bearing from external contaminants such as dirt, water, and debris. This protection is essential for maintaining long-term performance and preventing premature bearing failure.

Seal Types: Advanced seals are used to keep lubricants within the bearing and shield it from environmental contaminants. This feature is crucial for maintaining lubrication levels and ensuring the bearing operates smoothly over its lifespan.

Applications of Double Row Tapered Roller Bearings

Automotive Wheel Hubs

In the automotive sector, double row tapered roller bearings are commonly employed in wheel hubs, providing essential support for wheel rotation. They are used in both front and rear wheel hubs, where they handle significant radial and axial loads.

Function in Vehicles: These bearings ensure smooth wheel operation and support the vehicle’s weight while absorbing the forces encountered during driving. Their robust design makes them ideal for high-load applications in vehicles.

Heavy Machinery

Beyond automotive uses, these bearings are integral to heavy machinery and industrial equipment. Their ability to handle substantial loads makes them suitable for various applications in machinery that demands high performance and reliability.

Industrial Applications: In heavy machinery, double row tapered roller bearings are used in gearboxes, conveyor systems, and other equipment where reliable load support and durability are critical. Their high load capacity and resilience under tough conditions make them indispensable.

Quality Control Measures

Material Selection and Testing

Raw Material Inspection: We perform thorough inspections and tests on raw materials to ensure they meet stringent quality standards. This includes chemical composition analysis and mechanical testing to verify material properties.

Precision Manufacturing

Dimensional Accuracy: Our manufacturing processes employ advanced techniques to guarantee precise dimensions and tolerances. Automated machinery and regular calibration ensure uniformity and consistency across production batches.

Comprehensive Testing

Multi-Stage Testing: Bearings undergo extensive testing, including assessments of dimensional accuracy, load capacity, and rotational speed. Endurance tests simulate various operating conditions to ensure long-term reliability and performance.

Certification and Compliance

Standards Adherence: We adhere to international quality standards such as ISO 9001, demonstrating our commitment to maintaining high-quality manufacturing processes. Regular audits and reviews ensure ongoing compliance with industry standards.

Customer Feedback and Continuous Improvement

Feedback Integration: We actively incorporate customer feedback to enhance our products and processes. Our commitment to continuous improvement drives research, development, and innovation in bearing technology.

Installation and Maintenance Tips

Proper Installation

Tools and Techniques: Use the correct tools and follow the manufacturer’s specifications for torque and alignment to avoid damage. Avoid excessive force to prevent bearing or component damage.

Regular Lubrication

Lubricant Quality: Apply the recommended lubricant type and amount, ensuring it is clean and free from contaminants. Regularly check and replenish lubrication to maintain optimal performance.

Correct Fit and Alignment

Alignment Checks: Ensure the bearing fits correctly within its housing and on the shaft. Regularly verify alignment using precision tools to prevent uneven wear and premature failure.

Proper Handling

Handling Care: Handle bearings carefully to avoid physical damage during transportation and installation. Use clean gloves to prevent contamination and avoid dropping or striking the bearing.

By adhering to these design principles, quality control measures, and maintenance tips, you can ensure the reliability and performance of double row tapered roller bearings across various demanding applications.

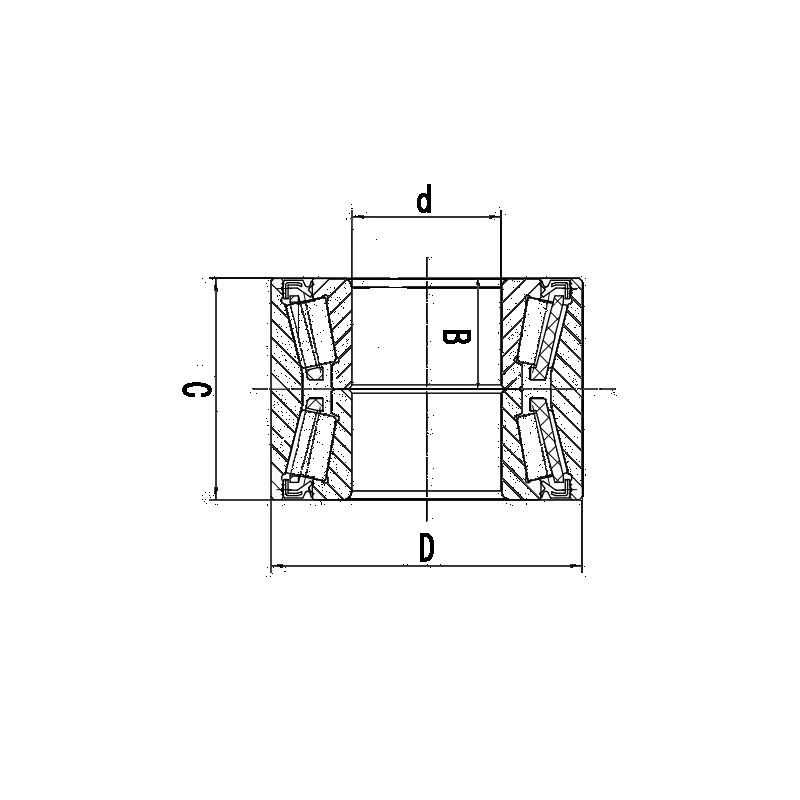

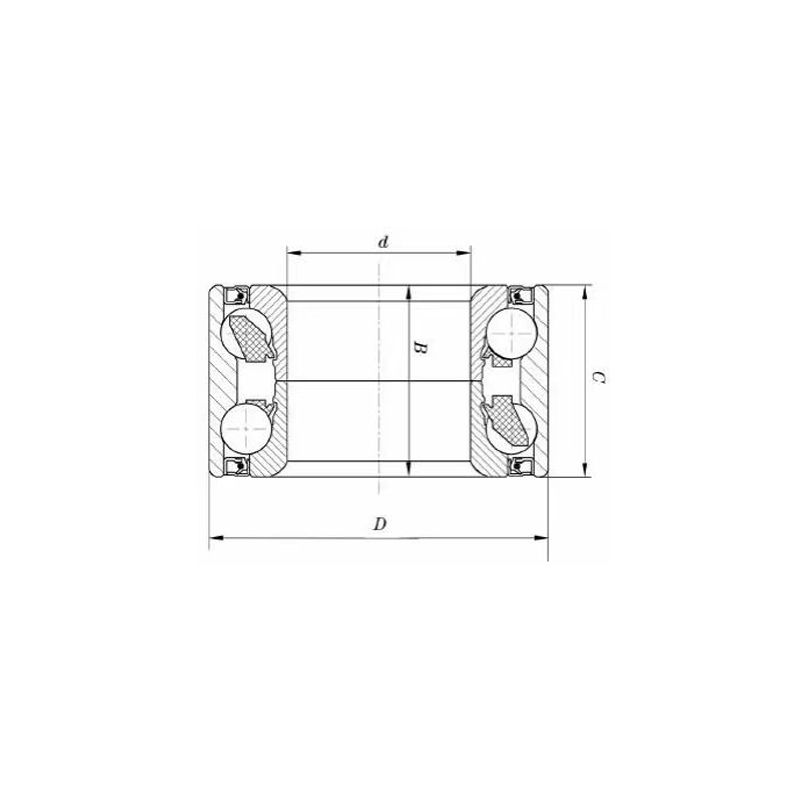

Technical Data:

| VANKV No. | Dimensions (mm) | Weight(kg) | Corresponding to the model | |||||

| d | D | B | C | SKF | FAG | KOYO | ||

| Du25520037 | 25 | 52 | 18.5 | 37 | 0.359 | |||

| DU25520037 | 25 | 52 | 18.5 | 37 | 0.358 | |||

| DU35520043 | 25 | 52 | 21.5 | 43 | 0.424 | |||

| DU25550043-2RS | 25 | 55 | 21.5 | 43 | 0.497 | |||

| DU25550045 | 25 | 55 | 22.5 | 45 | 0.523 | |||

| DU25550048-RZ | 25 | 55 | 24 | 48 | 0.568 | |||

| DU25620048 | 25 | 62 | 24 | 48 | 0.589 | |||

| DU25640038/254 | 25 | 64 | 19 | 25.4 | 0.623 | |||

| DU25640038.2/276 | 25 | 64 | 19.1 | 27.6 | 0.653 | |||

| DU27520045/43 | 27 | 52 | 22.5 | 43 | 0.418 | |||

| DU27530043-2RS | 27 | 53 | 21.5 | 43 | 0.435 | |||

| DU28540039 | 28 | 54 | 19.5 | 39 | 0.408 | |||

| DU29530037-2RS | 29 | 53 | 18.5 | 37 | 0.354 | |||

| DU30540039 | 30 | 54 | 19.5 | 39 | 0.38 | |||

| DU30540047/39 | 30 | 54 | 23.5 | 39 | 0.422 | |||

| DU30550027/25 | 30 | 55 | 13.5 | 25 | 0.294 | |||

| DU30580042 | 30 | 58 | 21 | 42 | 0.49 | |||

| DU30620048-RZ | 30 | 62 | 24 | 48 | 0.687 | |||

| DU325800651/57 | 32 | 58 | 32.55 | 57 | 0.641 | |||

| DU34640037 | 34 | 64 | 18.5 | 37 | 0.535 | |||

| DU35650035-RZ | 35 | 65 | 17.5 | 35 | 0.447 | |||

| DU36640037 | 36 | 64 | 18.5 | 37 | 0.497 | |||

| DU36640062/47 | 36 | 64 | 31 | 47 | 0.704 | |||

| DU36680062/52 | 36 | 68 | 31 | 52 | 0.911 | |||

| DU38640032/29 | 38 | 64 | 16 | 29 | 0.414 | |||

| DU38640036/33 | 38 | 64 | 36 | 33 | 0.45 | |||

| DU38650052/48 | 38 | 65 | 26 | 48 | 0.631 | |||

| DU38650052/48 | 38 | 65 | 26 | 48 | 0.65 | |||

| DU381700039/37 | 38.1 | 70 | 19.5 | 37 | 0.608 | |||

| DU39680037 | 39 | 68 | 18.5 | 37 | 0.559 | |||

DAC Wheel Hub Bearing: Comprehensive Overview and Quality Assurance

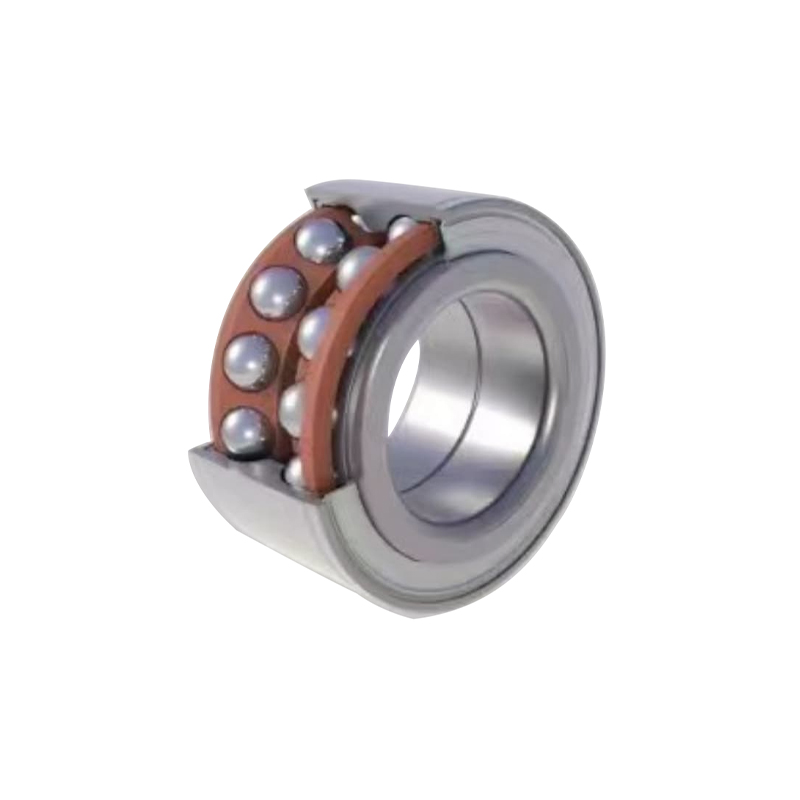

DAC wheel hub bearings, also known as Double Angular Contact ball bearings, are pivotal components in the automotive industry. Their design integrates two sets of ball bearings into a single unit, allowing them to manage both radial and axial loads from multiple directions simultaneously. This capability makes them indispensable in ensuring the smooth operation and longevity of vehicle wheel hubs. Let’s delve deeper into their structure, quality control measures, and maintenance tips.

Structure of DAC Wheel Hub Bearing

Inner Rings: DAC wheel hub bearings are equipped with two inner rings (or occasionally a single split inner ring) that mount onto the wheel hub or axle shaft. These rings are integral to the bearing’s ability to handle radial and axial loads. Each inner ring features raceways on both sides, which serve as the pathways for the balls to roll. This design enhances the bearing’s load-carrying capacity and stability.

Outer Ring: The bearing includes a single outer ring that surrounds the inner rings and provides the structural support needed for the assembly. This outer ring is designed with raceways that accommodate the balls, ensuring a stable and reliable bearing performance. Its robust construction helps in distributing loads evenly and maintaining the integrity of the bearing assembly.

Balls: The bearing is designed with multiple rows of balls, typically arranged in a double-row configuration. This arrangement is critical for supporting both radial and axial loads effectively. The balls are precisely manufactured to ensure uniform size and smooth rolling motion, which contributes to the overall efficiency and durability of the bearing.

Cage: A cage or separator is employed to keep the balls evenly spaced and guide their motion. The cage plays a crucial role in maintaining the bearing’s operational smoothness by preventing the balls from coming into contact with each other. This not only reduces friction but also minimizes wear and enhances the bearing’s lifespan.

Seals: DAC wheel hub bearings are equipped with seals to prevent the ingress of contaminants such as dirt, water, and debris. These seals are essential for maintaining the cleanliness of the internal components and retaining the lubricant. Effective sealing ensures the longevity and consistent performance of the bearing by protecting it from environmental factors.

Quality Control Measures

Ensuring the quality of DAC wheel hub bearings involves a comprehensive and rigorous quality control process to meet high standards of performance and reliability. This multifaceted approach begins with meticulous raw material inspection. The quality of deep groove ball bearings is contingent upon the careful selection of materials, which is achieved through thorough inspections and testing. We perform chemical composition analysis and mechanical testing to ensure that the materials are suitable for bearing production. Detailed records of material batches are maintained, facilitating the traceability of any defects and ensuring consistent quality throughout the production process.

The precision manufacturing phase utilizes advanced techniques to guarantee precise dimensions and tolerances. Our manufacturing processes are supported by automated machinery that ensures uniformity across large production batches. This reduces the risk of defects and maintains high-quality output. Regular calibration and inspection of machinery are critical to maintaining tight tolerances, ensuring that the bearings meet the required specifications.

Comprehensive testing is integral to our quality control process. Bearings undergo precision measuring to verify their dimensions, including inner and outer ring diameters, width, and ball sizes. Load and speed testing is conducted under simulated operating conditions to confirm that the bearings can handle specified loads and speeds without failure. This assessment is crucial for evaluating the bearing’s performance under real-world conditions. Additionally, endurance testing is performed to determine the long-term reliability and performance of the bearings. This includes testing under various operating conditions to simulate the bearing’s lifespan and ensure its durability.

Certification and compliance with international standards, such as ISO 9001, reflect our commitment to maintaining high-quality manufacturing practices. Regular audits and reviews are conducted to ensure ongoing adherence to industry standards. This certification provides assurance of our dedication to quality and reliability. Furthermore, we engage in continuous improvement initiatives to refine our processes and enhance product quality. Incorporating new technologies and methodologies allows us to stay at the forefront of bearing technology and continuously improve our offerings.

Customer feedback plays a vital role in our quality control processes. We actively seek and integrate feedback to address any areas for improvement and make necessary adjustments to our products. This customer-centric approach helps us enhance our bearings and ensure they meet the needs of our clients. Our technical support team is also available to provide guidance on the correct use, installation, and maintenance of bearings. This support ensures that customers receive optimal performance from our products and assists in resolving any issues that may arise.

In summary, our quality control process for DAC wheel hub bearings is thorough and multi-dimensional. From the initial raw material inspection through precision manufacturing and comprehensive testing to adherence to international standards, every step is carefully managed to ensure high performance and reliability. Continuous improvement and customer feedback further enhance our products, making sure they consistently meet and exceed expectations.

Technical Data:

| VANKV No. | Dimensions(mm) | Weight(kg) | Corresponding to the model | |||||

| d | D | B | C | SKF | FAG | KOYO | ||

| DAC28610042 | 28 | 61 | 42 | 42 | 0.53 | (28bwd01a) | ||

| DAC124000183 | 12 | 40 | 18.3 | 18.3 | 0.11 | C-00187 | ||

| DAC20420030/29 | 20 | 42 | 30 | 29 | 0.17 | 265592J22 | 539816 | |

| DAC205000206 | 20 | 50 | 20.6 | 20.6 | 0.21 | 156704 | ||

| DAC2050002068 | 20 | 50 | 20.6 | 20.6 | 0.22 | 320104 | ||

| DAC2184800206/18 | 21.8 | 48 | 20.6 | 18 | 0.25 | CBK506 | ||

| DAC254650027/24 | 25.4 | 65 | 27 | 24 | 0.41 | |||

| DAC255200206/23 | 25 | 52 | 20.6 | 23 | 0.33 | VBF256705 | ||

| DAC25520037 | 25 | 52 | 37 | 37 | 0.31 | 445539A | 576467 | |

| DAC25520037S | 25 | 52 | 37 | 37 | 0.31 | FC12025 | ||

| DAC25520042 | 25 | 52 | 42 | 42 | 0.34 | (25BWD01) | DAC2552W-9 2RS | |

| DAC25520043 | 25 | 52 | 43 | 43 | 0.35 | DAC2552BW-1 | ||

| DAC25550043 | 25 | 55 | 43 | 43 | 0.36 | BAH0059 | (IR-2222) | |

| DAC25560029/206 | 25 | 56 | 29 | 20.6 | 0.32 | 633272 | ||

| DAC25560032 | 25 | 56 | 32 | 32 | 0.34 | BAH5000 | ||

| DAC25720043 | 25 | 72 | 43 | 43 | 0.65 | |||

| DAC27520045 | 27 | 52 | 45 | 45 | 0.36 | |||

| DAC27530043 | 27 | 53 | 43 | 43 | 0.36 | 27BWD01J | (IR-8653) | DAC01WD07 |

| DAC27600050 | 27 | 60 | 50 | 50 | 0.56 | 28BWD03A | DAC28582RK | |

| DAC28580042 | 28 | 58 | 42 | 42 | 0.45 | 28BWD01A | ||

| DAC28580044 | 28 | 58 | 44 | 44 | 0.48 | |||

| DAC28610042 | 28 | 61 | 42 | 42 | 0.53 | 801023A | ||

| DAC29530037 | 29 | 53 | 37 | 37 | 0.34 | NTN DE0678 | ||

| DAC30500020 | 30 | 50 | 20 | 20 | 0.13 | NEN DE0681 | ||

| DAC30540024 | 30 | 54 | 24 | 24 | 0.36 | ATV-BB-2 | ||

| DAC30550030/25 | 30 | 55 | 30 | 25 | 0.39 | DAC3055WCS31 | ||

| DAC30550032 | 30 | 55 | 32 | 32 | 0.27 | |||

| DAC30580042 | 30 | 58 | 42 | 42 | 0.48 | 6-256706E1 | ||

| DAC30600037 | 30 | 60 | 37 | 37 | 0.42 | 633313C | VBF6-256706 | 545312 |

| DAC30600337 | 30 | 60.03 | 37 | 37 | 0.42 | BA2B243739CA | ||

| DAC00034/34 | 30 | 60 | 37 | 34 | 0.4 | 30BVV06 | ||

| DAC30620032 | 30 | 62 | 32 | 32 | 0.36 | IR-8004 | ||

| DAC30620037 | 30 | 62 | 37 | 37 | 0.42 | 30BWD10 | ||

| DAC30620038 | 30 | 62 | 38 | 38 | 0.43 | |||

| DAC30620044 | 30 | 62 | 44 | 44 | 0.44 | 30BWD01A | DAC3063W-1 | |

| DAC30630042 | 30 | 63 | 42 | 42 | 0.47 | |||

| DAC30640037 | 30 | 64 | 37 | 37 | 0.47 | 522372 | DAC3064WRKB | |

| DAC30640042 | 30 | 64 | 42 | 42 | 0.49 | 630374/C4 | IR-8014 | |

| DAC30650021 | 30 | 65 | 21 | 21 | 0.27 | 320406 | ||

| DAC306500264 | 30 | 65 | 26.4 | 26.4 | 0.36 | 30BWD04 | 3306 | |

| DAC30680045 | 30 | 68 | 45 | 45 | 0.52 | |||

| DAC307200302 | 30 | 72 | 30.2 | 30.2 | 0.31 | BAHB636035 | ||

| DAC30720037 | 30 | 72 | 37 | 37 | 0.48 | 32BWD05 | ||

| DAC30720045 | 32 | 72 | 45 | 45 | 0.6 | |||

| DAC32580065/57 | 32 | 58 | 65 | 57 | 0.6 | |||

| DAC32720034 | 32 | 72 | 34 | 34 | 0.6 | |||

| DAC34620037 | 34 | 62 | 37 | 37 | 0.41 | 309724 | 561447 | |

| DAC34640037 | 34 | 64 | 37 | 37 | 0.43 | 309726DA | VBF 6-256907 | |

| DAC34660037 | 34 | 66 | 37 | 37 | 0.41 | 636114A | 580400CA | |

| DAC34670037 | 34 | 67 | 37 | 37 | 0.44 | 803775 | ||

| DAC356180031 | 35 | 61.8 | 31 | 31 | 0.35 | DAC3562AW | ||

| DAC35620040 | 35 | 61.8/62 | 40 | 40 | 0.42 | DAC3562W-5CS35 | ||

| DAC35640037 | 35 | 64 | 37 | 37 | 0.41 | DAC3564A-1 | ||

| DAC35640037A10.15 | 35 | 64 | 37 | 37 | 0.43 | |||

| DAC35650035 | 35 | 65 | 35 | 35 | 0.4 | BT2B445620B | 546238A | |

| DAC35660032 | 35 | 66 | 32 | 32 | 0.42 | 445980A | ||

| DAC35660033 | 35 | 66 | 33 | 33 | 0.43 | BAHB633676 | ||

| DAC35660037 | 35 | 66 | 37 | 37 | 0.48 | BAHB311309 | 544307 | (BAHB0023) |

| DAC35670042 | 35 | 67 | 42 | 42 | 0.45 | (35BWD24) | ||

| DAC35680233/30 | 35 | 68.02 | 33 | 30 | 0.47 | (35BWD07) | DAC3568W-6 | |

| DAC35680037 | 35 | 68 | 37 | 37 | 0.48 | PLC15-12 | GB12132S03 | DAC3568A2RS |

| DAC35680042 | 35 | 68 | 42 | 42 | 0.52 | |||

| DAC35680045 | 35 | 68 | 45 | 45 | 0.52 | |||

| DAC35720027 | 35 | 72 | 27 | 27 | 0.43 | |||

| DAC35720028 | 35 | 72.02 | 28 | 28 | 0.44 | BA2B441832AB | 544033 | |

| DAC35720033 | 35 | 72 | 33 | 33 | 0.58 | BAHB633669 | 548083 | GB12094 |

| DAC35720034 | 35 | 72 | 34 | 34 | 0.6 | (35BWD01) | 540763 | DAC357234A |

| DAC35720233/31 | 35 | 72.02 | 33 | 31 | 0.56 | (35BWD06A) | DAC357233B-1W | |

| DAC35720433 | 35 | 72.04 | 33 | 33 | 0.58 | BA2B446762B | GB12862 | |

| DAC35720042 | 35 | 72 | 42 | 42 | 0.7 | |||

| DAC35720045 | 35 | 72 | 45 | 45 | 0.72 | |||

| DAC35760054 | 35 | 76 | 54 | 54 | 0.84 | 35BWD10 | ||

| DAC36640037A10.30 | 36 | 64 | 37 | 37 | 0.42 | |||

| DAC36640037A40.80 | 36 | 64 | 37 | 37 | 0.42 | |||

| DAC36640042 | 36 | 64 | 42 | 42 | 0.46 | |||

| DAC36680033 | 36 | 68 | 33 | 33 | 0.5 | DAC3668AW | ||

| DAC36720434 | 36 | 72.04 | 34 | 34 | 0.58 | |||

| DAC36720534 | 36 | 72.05 | 34 | 34 | 0.58 | 36BWD01C | 559225 | DAC367234A |

| DAC367600292/27 | 36 | 76 | 29.2 | 27 | 0.58 | 440190C | ||

| DAC37680045 | 37 | 68 | 45 | 45 | 0.72 | |||

| DAC37720033S | 37 | 72 | 33 | 33 | 0.58 | BAH0051B | (GB40547) | |

| DAC37720537-M | 37 | 72.05 | 37 | 37 | 0.6 | BAH0055AAX | ||

| DAC37720033-M | 37 | 72 | 33 | 33 | 0.54 | BAH0072AB | ||

| DAC37720037 | 37 | 72 | 37 | 37 | 0.59 | TGB40547 | (GB12807.S03) | |

| DAC37720237 | 37 | 72.02 | 37 | 37 | 0.59 | BA2B633028 | 527631 | (GB12258) |

| DAC37720437 | 37 | 72.04 | 37 | 37 | 0.59 | 579794 | (GB12131) | |

| DAC37740045 | 37 | 74 | 45 | 45 | 0.79 | 309946AC | 541521C | |

| DAC37700052/45 | 37 | 70 | 52 | 45 | 0.7 | |||

| DAC38700040 | 38 | 70 | 40 | 40 | 0.58 | |||

| DAC38710233/30 | 37.99 | 71.02 | 33 | 30 | 0.5 | (38BWDD09) | DAC3871W-2 | |

| DAC38720036/33 | 38 | 72 | 36 | 33 | 0.54 | (38BWD12) | DAC3872W-3(-8) | |

| DAC38740036/33 | 38 | 74 | 36 | 33 | 0.58 | (38BWD15) | 574795 | DAC3874W-6 |

| DAC38700037 | 38.1 | 70 | 37 | 37 | 0.52 | 636193A | ||

| DAC38700038 | 38 | 70 | 38 | 38 | 0.55 | DAC3870BW | ||

| DAC38710039 | 38 | 71 | 39 | 39 | 0.62 | (38BWDD22) | DAC3871W-3 | |

| DAC38720034 | 38 | 72 | 34 | 34 | 0.46 | (38BWDD04) | DAC3872ACS42 | |

| DAC38720040 | 38 | 72 | 40 | 40 | 0.63 | DAC3872W-10 | ||

| DAC38730040 | 38 | 73 | 40 | 40 | 0.65 | DAC3873-W | ||

| DAC38730040-M | 38 | 73 | 40 | 40 | 0.67 | (38BWD26E1) | ||

| DAC38740040 | 38 | 74 | 40 | 40 | 0.68 | |||

| DAC38740050 | 38 | 74 | 50 | 50 | 0.78 | 38BWD06 | 559192 | NTNDE0892 |

| DAC38740036 | 38 | 74 | 36 | 36 | 0.46 | |||

| DAC38790045 | 38 | 79 | 45 | 45 | 0.96 | |||

| DAC39670037 | 39 | 67 | 37 | 37 | 0.46 | |||

| DAC39680037 | 39 | 68 | 37 | 37 | 0.48 | BA2B309692 | 540733 | |

| DAC39680737 | 39 | 68.07 | 37 | 37 | 0.48 | 309639 | ||

| DAC39720037 | 39 | 72 | 37 | 37 | 0.56 | BAHB311396B | 542186A | DAC3972AW4 |

| DAC39720437 | 39 | 72.04 | 37 | 37 | 0.56 | BAH0106DX | ||

| DAC39720637 | 39 | 72.06 | 37 | 37 | 0.55 | |||

| DAC39740036/34 | 39 | 74 | 36 | 34 | 0.62 | |||

| DAC39740034 | 39 | 74 | 34 | 34 | 0.6 | |||

| DAC39740038 | 39 | 74 | 38 | 38 | 0.65 | 636096A | ||

| DAC39740039 | 39 | 74 | 39 | 39 | 0.66 | BAHB633815A | 579557 | |

| DAC39/41750037 | 39/41 | 75 | 37 | 37 | 0.62 | 567447B | ||

| DAC39997208331A10.15 | 39.99 | 72.08 | 33.1 | 33.1 | 0.44 | |||

| DAC40680042 | 40 | 68 | 42 | 42 | 0.51 | |||

| DAC40700040 | 40 | 70 | 40 | 40 | 0.56 | |||

| DAC40720036 | 40 | 72 | 36 | 36 | 0.54 | BAHD311433B | ||

| DAC40720037 | 40 | 72 | 37 | 37 | 0.55 | 566719 | ||

| DAC40720036/33 | 40 | 72 | 36 | 33 | 0.54 | 801663D | DAC4072W-3CS35 | |

| DAC40720437 | 40 | 72.04 | 37 | 37 | 0.55 | |||

| DAC40720637 | 40 | 72.06 | 37 | 37 | 0.55 | |||

| DAC40730055 | 40 | 73 | 55 | 55 | 0.58 | |||

| DAC40740036/34 | 40 | 74 | 36 | 34 | 0.58 | |||

| DAC40740036 | 40 | 74 | 36 | 36 | 0.6 | AU0817-5 | DAC4074CWCS73 | |

| DAC407404840A40.80 | 40 | 74.048 | 40 | 40 | 0.67 | 40BWD15 | ||

| DAC407404840A10.15 | 40 | 74.048 | 40 | 40 | 0.67 | |||

| DAC40740040 | 40 | 74 | 40 | 40 | 0.66 | 801136 | 559493 | |

| DAC40740042 | 40 | 74 | 42 | 42 | 0.7 | 40BWD12 | ||

| DAC40750037-M | 40 | 75 | 37 | 37 | 0.64 | 40BWD17 | ||

| DAC40750037 | 40 | 75 | 37 | 37 | 0.62 | BAHB633966 | 559494 | |

| DAC40750039-M | 40 | 75 | 39 | 39 | 0.69 | 40BWD17D | ||

| DAC40760033 | 40 | 76 | 33 | 33 | 0.55 | 555800 | ||

| DAC40760033/28 | 40 | 76 | 33 | 28 | 0.54 | 474743 | 539166AB | |

| DAC40760036 | 40 | 76 | 36 | 36 | 0.55 | |||

| DAC40760041/38 | 40 | 76 | 41 | 38 | 0.66 | 40BWD05 | DAC406412RS | |

| DAC40800302 | 40 | 80 | 30.2 | 30.2 | 0.65 | 440320H | 565636 | |

| DAC40800036/34 | 40 | 80 | 36 | 34 | 0.7 | DAC4080M1 | ||

| DAC40800381 | 40 | 80 | 38.1 | 38.1 | 0.75 | 534682B | ||

| DAC40820040 | 40 | 82 | 40 | 40 | 0.8 | |||

| DAC40840034 | 40 | 84 | 34 | 34 | 0.94 | |||

| DAC40840038 | 40 | 84 | 38 | 38 | 0.96 | GB40250 | ||

| DAC40800040 | 40 | 80 | 40 | 40 | 0.83 | |||

| DAC408406387/397-M | 40 | 84.06 | 38.7 | 39.7 | 0.95 | XGB40492S01P | ||

| DAC40842538 | 40 | 84.025 | 38 | 38 | 0.97 | GB40250S01 | ||

| DAC40900046 | 40 | 90 | 46 | 46 | 0.92 | (PT40900046) | ||

| DAC401080032/17 | 40 | 108 | 32 | 17 | 1.2 | BA2B445533 | (TGB10872S02) | |

| DAC42720038/35 | 42 | 72 | 38 | 35 | 0.54 | |||

| DAC42720038 | 42 | 72 | 38 | 38 | 0.66 | |||

| DAC42750037 | 42 | 75 | 37 | 37 | 0.59 | 309245 | 545495D | |

| DAC42720037 | 42 | 72 | 37 | 37 | 0.6 | |||

| DAC42750045 | 42 | 75 | 45 | 45 | 0.63 | |||

| DAC42760033 | 42 | 76 | 33 | 33 | 0.56 | 555801 | ||

| DAC42760037 | 42 | 76 | 37 | 37 | 0.62 | |||

| DAC42760038/35 | 42 | 76 | 38 | 38 | 0.58 | (42BWD06) | (IR8650) | |

| DAC42760039 | 42 | 76 | 39 | 39 | 0.62 | 579102 | ||

| DAC42760040/37 | 42 | 76 | 40 | 37 | 0.64 | 909042 | 547059A | DAC427640 2RSF |

| DAC42760037/35 | 42 | 76 | 37 | 35 | 0.56 | |||

| DAC42780038 | 42 | 78 | 38 | 38 | 0.65 | DAC4278A 2RSF | ||

| DAC42780040 | 42 | 78 | 40 | 40 | 0.66 | |||

| DAC42780045-M | 42 | 78 | 45 | 45 | 0.7 | |||

| DAC42800042 | 42 | 80 | 42 | 42 | 0.8 | |||

| DAC42780045 | 42 | 78 | 45 | 45 | 0.68 | |||

| DAC42780038 | 42 | 78 | 38 | 38 | 0.64 | 42BWD09 | 42BW09 | |

| DAC42800036/34 | 42 | 80 | 36 | 34 | 0.7 | BAH0117 | ||

| DAC42800037 | 42 | 80 | 37 | 37 | 0.79 | BAHB633770 | ||

| DAC42800045 | 42 | 80 | 45 | 45 | 0.85 | DAC4280W-2CS40 | ||

| DAC42800342 | 42 | 80.03 | 42 | 42 | 0.81 | BA2B309609AD | 527243C | DAC4280B 2RS |

| DAC42820036 | 42 | 82 | 36 | 36 | 0.77 | BA2B446047 | 561481 | (GB12163 S04) |

| DAC42820036-ZZ-M | 42 | 82 | 36 | 36 | 0.78 | BAH0186 | ||

| DAC42820037 | 42 | 82 | 37 | 37 | 0.77 | 565636 | (GB12269) | |

| DAC42840034 | 42 | 84 | 34 | 34 | 0.75 | |||

| DAC42840036 | 42 | 84 | 36 | 36 | 0.88 | BA2B444090A | 564727 | (GB10857 S02) |

| DAC42840037 | 42 | 84 | 37 | 37 | 0.91 | |||

| DAC42840039 | 42 | 84/84.03 | 39 | 39 | 0.93 | 440090 | 543359B | (GB10702 S02) |

| DAC42842538 | 42 | 84.25 | 38 | 38 | 0.93 | |||

| DAC43720044/27 | 43 | 72 | 44 | 27 | 0.75 | |||

| DAC43760043 | 43 | 76 | 43 | 43 | 0.66 | (43BWD12A) | ||

| DAC43770042/38 | 43 | 77 | 42 | 38 | 0.64 | |||

| DAC43780044-RSZ-M | 43 | 78 | 44 | 44 | 0.79 | |||

| DAC43790041/38 | 43 | 79 | 41 | 38 | 0.84 | DAC4379-1 | ||

| DAC43790045 | 43 | 79 | 45 | 45 | 0.81 | |||

| DAC43800038 | 43 | 80 | 38 | 38 | 0.8 | |||

| DAC43800050/45 | 43 | 80 | 50 | 45 | 0.95 | (43BWD03) | DAC4380A | |

| DAC43820045 | 43 | 82 | 45 | 45 | 0.9 | (43BWD06) | DAC4382W-3CS79 | |

| DAC43/45820037 | 43/45 | 82 | 37 | 37 | 0.76 | BAHB633814A | 567519A | |

| DAC43/45850037 | 43/45 | 85 | 37 | 37 | 0.8 | |||

| DAC43997208331A10.15 | 43.99 | 72.08 | 33.1 | 33.1 | 0.47 | |||

| DAC448250037 | 44 | 82.5 | 37 | 37 | 0.76 | (GB40246S07) | ||

| DAC45850023 | 45 | 85 | 23 | 23 | 0.54 | 4209ATN9 | ||

| DAC45750027/15 | 45 | 75 | 27 | 15 | 0.48 | |||

| DAC45750023/15 | 45 | 75 | 23 | 15 | 0.47 | |||

| DAC45800045 | 45 | 80 | 45 | 45 | 0.95 | 564725AB | ||

| DAC45800045/44 | 45 | 80 | 45 | 44 | 0.95 | |||

| DAC45800048 | 45 | 80 | 48 | 48 | 0.99 | |||

| DAC45830044 | 45 | 83 | 44 | 44 | 0.9 | |||

| DAC45830045 | 45 | 83 | 45 | 45 | 0.92 | |||

| DAC45840038 | 45 | 84 | 38 | 38 | 0.87 | |||

| DAC45840039 | 45 | 84 | 39 | 39 | 0.88 | |||

| DAC45840041/39 | 45 | 84 | 41 | 39 | 0.9 | (45BWD03) | 309797 | |

| DAC45840042/40 | 45 | 84 | 42 | 40 | 0.9 | DAC4584DW | ||

| DAC45840042/40-2RS-M | 45 | 84 | 42 | 40 | 0.86 | (45BWD07) | ||

| DAC45840042 | 45 | 84 | 42 | 42 | 0.9 | (45BWD12J1) | ||

| DAC45840042/40 | 45 | 84 | 42 | 40 | 0.87 | |||

| DAC45840045 | 45 | 84 | 45 | 45 | 0.93 | 44300S84A02 | ||

| DAC458500302 | 45 | 85 | 30.2 | 30.2 | 0.83 | |||

| DAC45850041 | 45 | 85 | 41 | 41 | 0.9 | DAC2004 | ||

| DAC45850051 | 45 | 85 | 51 | 51 | 1 | |||

| DAC45850047 | 45 | 85 | 47 | 47 | 1 | |||

| DAC45860039 | 45 | 86 | 39 | 39 | 0.93 | |||

| DAC45870041/39 | 45 | 87 | 41 | 39 | 0.95 | |||

| DAC45880045 | 45 | 88 | 45 | 45 | 1.15 | |||

| DAC45880239 | 45 | 88.02 | 39 | 39 | 0.98 | |||

| DAC47810053 | 47 | 81 | 53 | 53 | 0.98 | |||

| DAC47850045 | 47 | 85 | 45 | 45 | 0.98 | 559431 | ||

| DAC45870041/39-M | 45 | 87 | 41 | 39 | 0.98 | |||

| DAC48820037/33 | 48 | 82 | 37 | 33 | 0.82 | |||

| DAC49840039 | 49 | 84 | 39 | 39 | 0.93 | |||

| DAC49840048 | 49 | 84 | 48 | 48 | 0.98 | |||

| DAC49880046 | 49 | 88 | 46 | 46 | 0.95 | 572506 | ||

| DAC504818833/28 | 50.379 | 81.883 | 33 | 28 | 0.78 | |||

| DAC50820033/28 | 50 | 82 | 33 | 28 | 0.78 | |||

| DAC50900034 | 50 | 90 | 34 | 34 | 0.83 | 633007C | 528514 | |

| DAC50900040 | 50 | 90 | 40 | 40 | 0.98 | |||

| DAC55900060 | 55 | 90 | 60 | 60 | 0.99 | |||

| DAC51910044 | 51 | 91 | 44 | 44 | 0.83 | |||

| DAC52910040 | 52 | 91 | 40 | 40 | 0.8 | |||